Excellent steels being manufactured worldwide for use in cutlery We respectfully disagree Carbon vs Stainless steel?Jul 23,·D2 steel is an alloy of high carbon and chromium giving it very superior hardness,wear,and corrosion resistance as compared to 1095 steelIn terms of cost,Carbon steels are always cheaper than alloy steel but for long and sturdy use,D2 steel is preferable1075 VS 1095 steelIn 1095,1 indicates carbon as the main alloying element1095 steel equivalent 1095 steel vs 5160 5160 steel is highend steel containing enough amounts of chromium to make it stainless steel, unlike 1095, which only contain carbon and manganese This makes 5160 harder and better in corrosion resistance 1095 vs 1084 Both steels are from the 10xx family

Carbon Myth

1095 carbon steel vs d2

1095 carbon steel vs d2-YES Global Elite Networking Global Resources Business Opportunities Home;This subject is huge, I'll have to probably make another video to explain in more detail

Amazon Com Gcs Handmade Hunting Knife Micarta Handle D2 Tool Steel Tactical Knife Skinning Knife Survival Knife With Buffalo Hide Leather Sheath Full Tang Blade Designed For Hunting Skinning Edc Gcs

For each property being compared, the top bar is AWS E90CD2 and the bottom bar is SAEAISI 1095 steel AWS E90CD2 or E62CD2 (W) Weld Metal SAEAISI 1095 (SUP4, , C100S, G) Carbon Steel The tradeoff is being more prone to corrosion given the low chromium content The most popular carbon knife steel is 1095 Tool Steel – primarily hard steel alloys used in cutting tools Some popular tool steels in this group include D2, O1 and Crucible's CPM series (ie CPM 3V) plus more advanced high speed steels like M4Designer and knifemaker Derick Rougeau torture tests 1095 and 5160 steel to be used for tactical machetes For more information on what he has to offer pleas

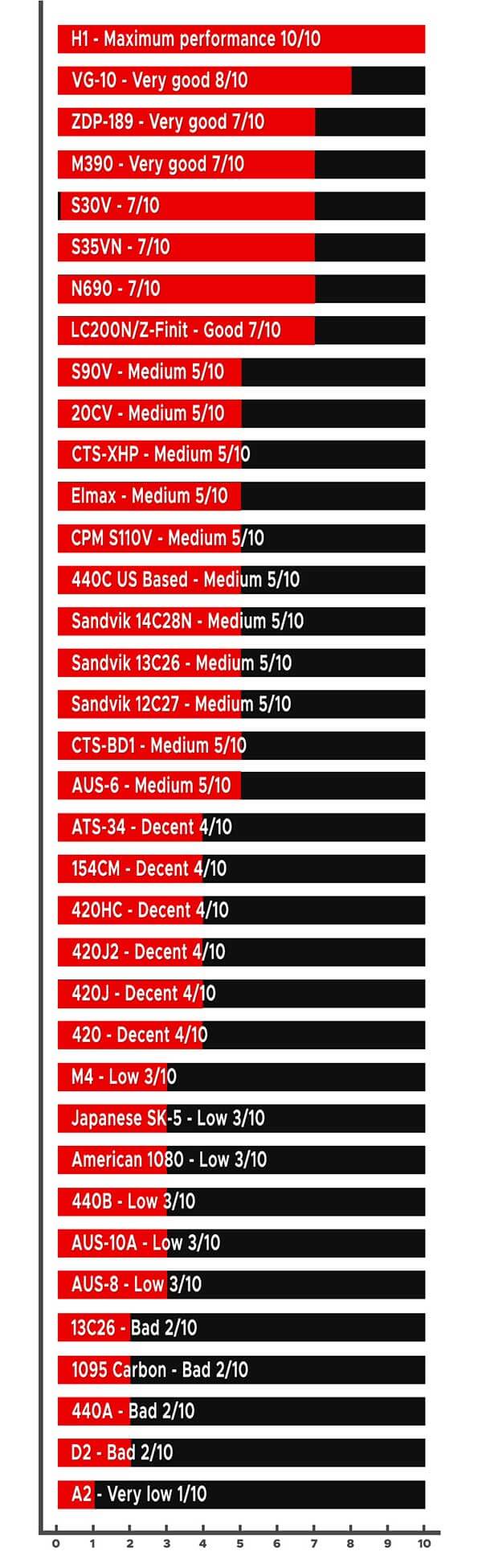

Plain carbon tool steels like 1075 1084 and 1095 have the potential to make superb knives, but nowadays have been rendered obsolete by alloy steels that will produce equally good or better results with less effort As a consequence most manufacturers treat 10xx steels as low end/budget material and heat treat it accordingly D2 steel vs 1095 Is D2 steel better than 1095?We all know the famous Izula, it comes on both the 1095 Carbon steel and the 440c stainless steel, the Bullet Ant or Izula is one of the greatest knives you can get with the 440C steel, this knife is more than outdoor knife it can serve you in many situations, it's lightweight, easy to sharpen and has a great edge retention, if you're looking for a hunting knife, camping knife or just any outdoor

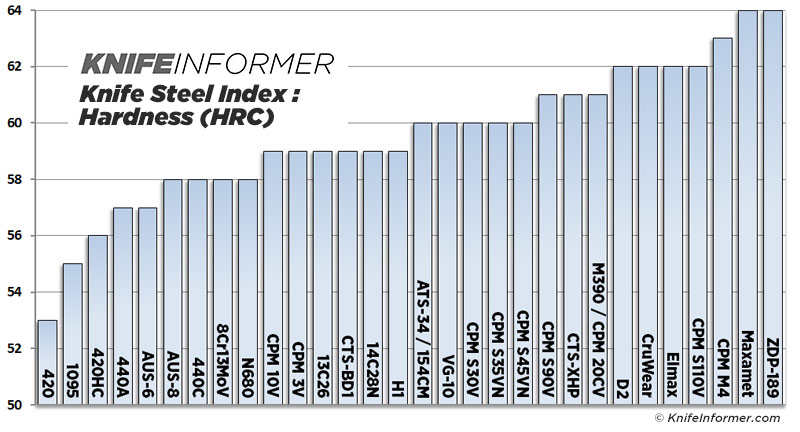

This type of steel can be used to make a knife, butThe higher the carbon content, the more you can heat treat and harden the metal Higher carbon content also makes it more difficult to weld Carbon steel generally is divided into three categories Low Carbon Steel AKA mild steel, where the carbon content is between 005 and 025%, with a maximum manganese content of 04% This is cheap stuff1095 was developed as a simple tool steel that proved very effective for knife blades when heat treated appropriately The high carbon content allows the steel to be quenched to a hardness of HRc66, but for knife blades the steel is usually drawn back (tempered) to 5658 HRc, which provides an optimum combination of hardness and toughness 1095 Steel Composition 095C

D2 Steel Is It A Good Knife Steel

A New Style Unique Design D2 Steel Bowie Knife With Leather Etsy D2 Steel Bowie Knife Leather Sheath

Yahoo Answers D2 vs 1095 SteelWhich One Is the Better Blade Material #01;The more carbon the harder the steel and the better the she but also more carbon makes the blade weak and brittle ,and the blade can chip and break easily1075 is a hood balance of hardness and toughness1075 has the hardness similar of 1095 to keep a good edge but isFor a steel to be classed as carbon steel, it must have a carbon element of at least 21% This type of steel also contains various other alloys, and these will vary significantly from one steel to the next Carbon steel has limitations on the amount of copper, manganese, and silicon that is includedFor example, it is true that in general 1095 will have a slightly higher amount of cementite than 1084 which will give it a higher wear resistance, but how much is likely not to be significant In some detail, from research looking at the wear on steels in grinding ore, here are the relative wear rates of 1040 carbon steel vs 1090 carbon steel 1

Aisi Steel Review 1095 Cro Van Steel Bearing Steel

O1 Tool Steel Guide Knifeup

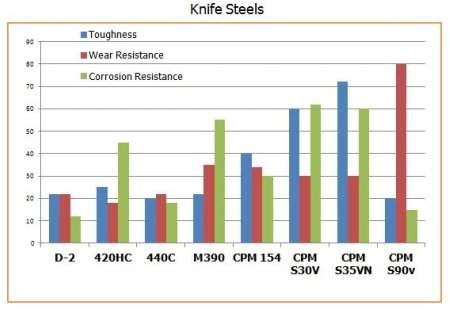

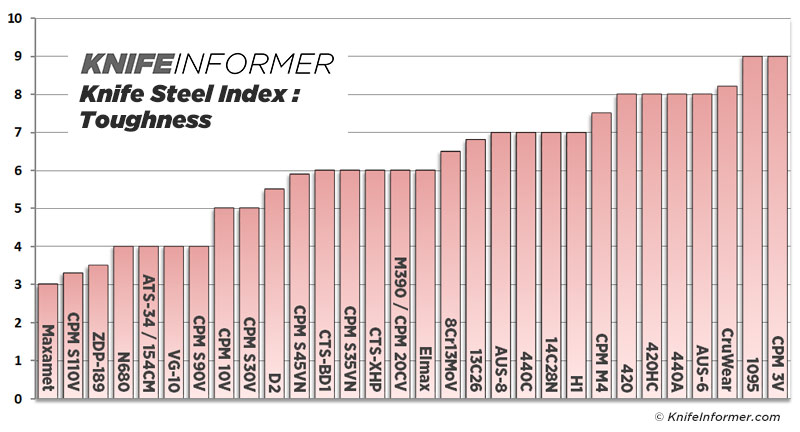

Carbon steels 1015 72% 1018 78% 10 72% 1022 78% 1030 70% 1040 64% 1042 64% 1050 54% 1095 42% 1117 91% 1137 72% 1141 70% 1141 annealed 81% From their data, (15%Cr) did require more torque than W1 (simple high carbon) steel 400 inlbs vs 300; D2 is a tool steel, tool steels are harder, hold an edge better, harder to sharpen and are more brittle 1095 is high in carbon, softer, easier to sharpen, does'nt hold an edge as well, is more flexable and rust easily

3

Is 1095 Steel Good For Knife Making

In the case of 1095 steel, the leading digit "1" identifies the metal as a carbon steel, the "0" shows that it contains no secondary alloying element, and the "95" represents its carbon content Among carbon steels, 1095 steel carries the further limitation that its carbon content should not exceed approximately 100% 1095 steel What are the pros and cons of both 1095 high carbon and D2 steels Click to expand D2 is optomized for wear resistance, it has a very high carbide fraction, this also makes it difficult to grind and it will in general fracture readily under impacts and isn't very flexible, Swamp Rat's heat treatment of D2 tends to make theirs a lot tougher than others thoughIn their composition, D2 is a high Chromium steel while Carbon level in 1095 is substantial As a result, the D2 can be called more or less a semistainless material and 1095 is a classic high carbon steelD2 vs 1095 Steel Which One Is the Better Blade Material?

Knife Blades Common Steels Explained Gearjunkie

How Good Is 1095 Steel

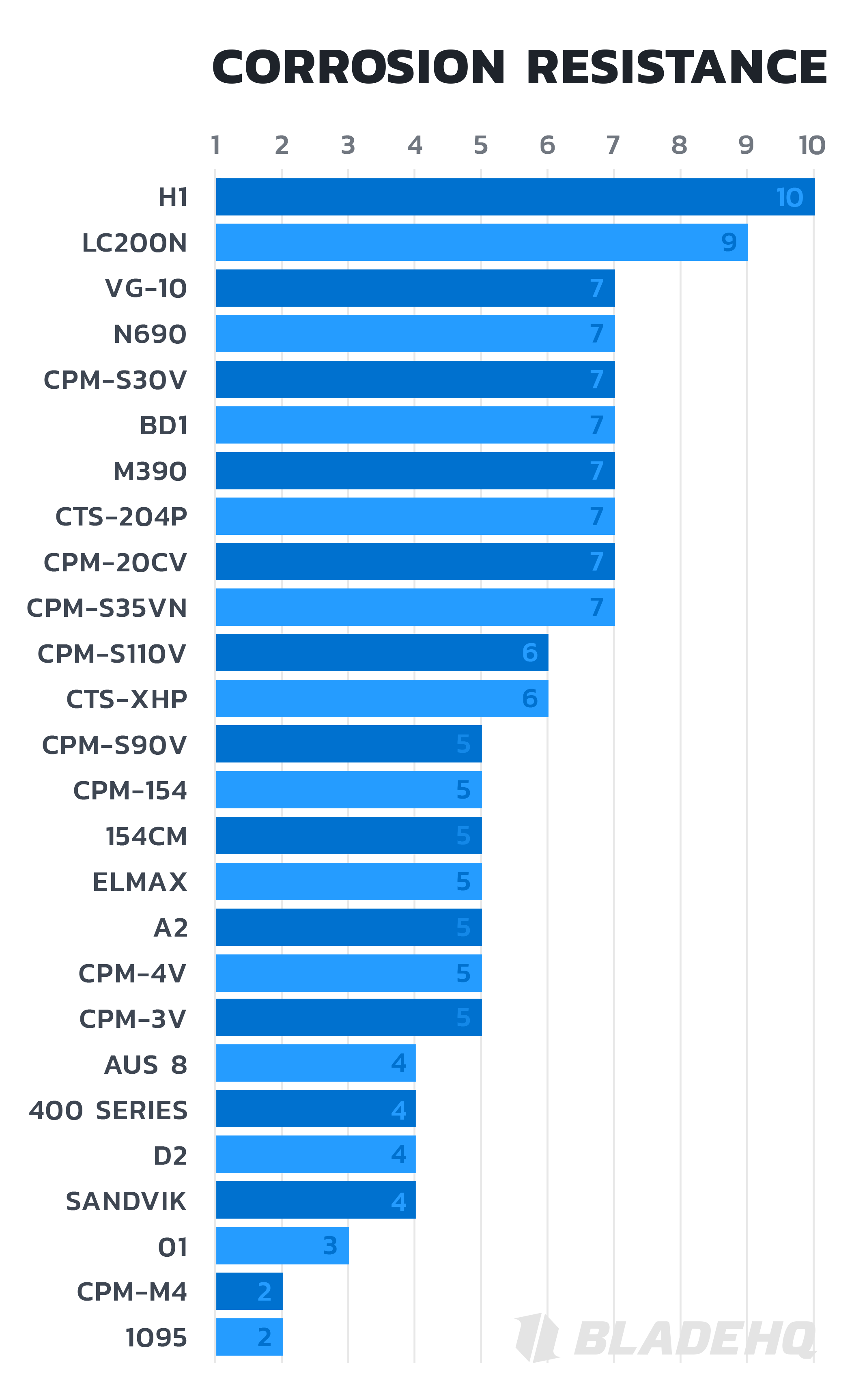

Though technically not a stainless steel — at least 14% chromium, and D2 usually has 12% — it's relatively corrosionresistant D2 has been around for more than years, an eternity in Properties of 1095 Steel 1095 Steel is a basic form of carbon steel and is most commonly used in the construction of various kinds of knives It has a carbon content of 95% which serves to harden the steel and reduce the amount of wear that a blade will experience over time Despite the reduction in wear created by the high presence of carbon,Average dew point, 7 °C (45 °F) 260 (500) 57 HRC

The Difference Between 440c Steel Vs D2 Compared Guide Knifeyellowpages

Torture Testing 1095 And 5160 Blade Steel Youtube

It is another type of carbon steel and you can say it is a child of the 1095 steel and as the rule of nature this is the improved version of its ancestors in terms of hardness because it has chromium, carbon, nickel, vanadium, and molybdenum more than the 1095 steel Many people are confused that it is not stainless steel because it has chromium but this statement is wrong To say something like S35VN is a better steel for a hard use camp knife than something like 1095 or 5160 is an absolute joke Great steels for edge retention, but powdered steels are significantly more brittle than carbon steels This is why most camp knives are made from carbon steels instead 1095 CRO Van Steel is high carbon steel derived from the famous 1095 steel by adding more carbon, nickel, chromium, molybdenum, and vanadium Other names used to refer to this steel include Sharon Steel 1095CV, B (named so by Bark River), B (formal name according to American Iron and Steel Institute), Carbon V, 1095CV, and steel

1095 Or D2 Survivalist Forum

Which Steels Are Easiest And Most Difficult To Forge Knife Steel Nerds

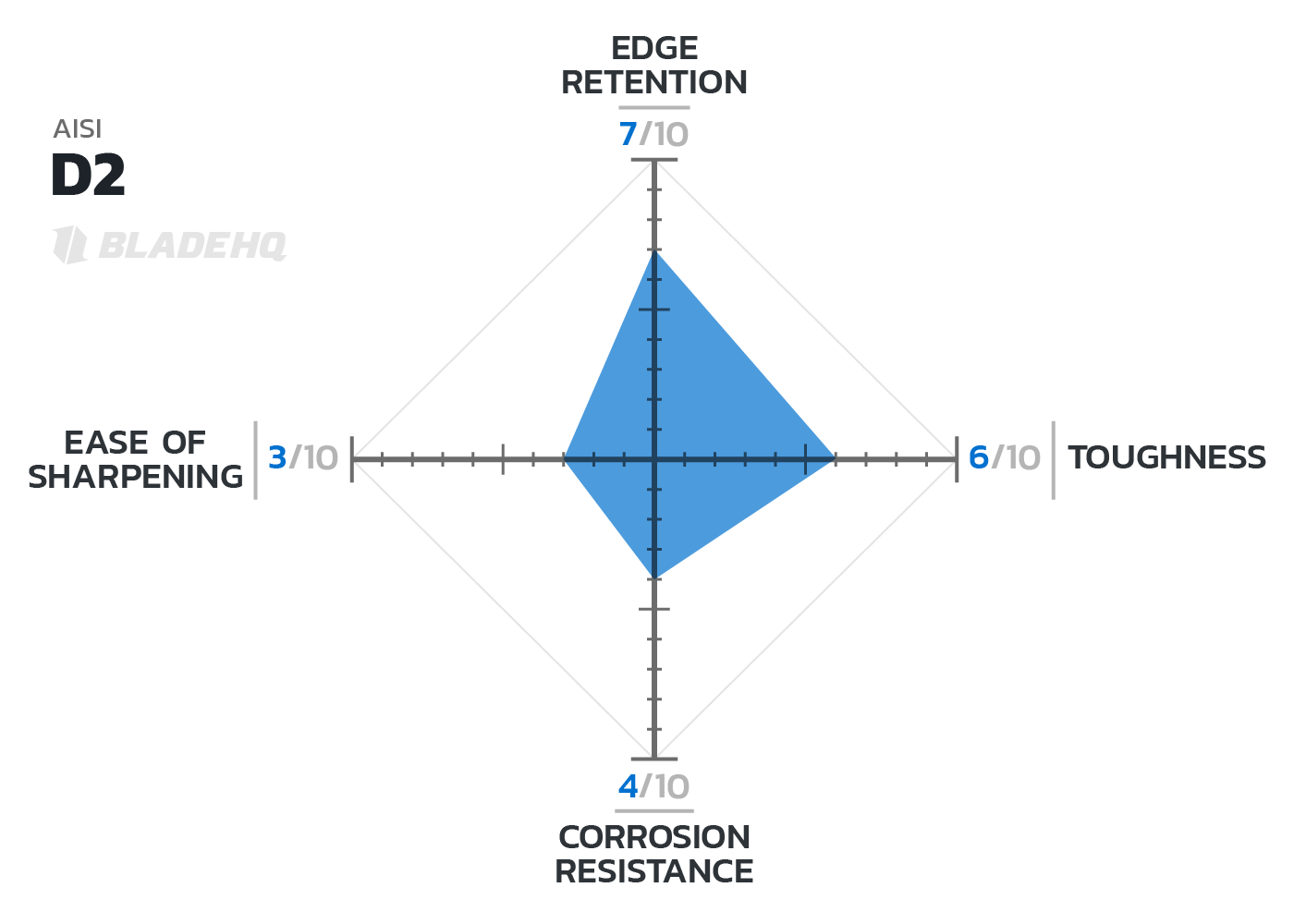

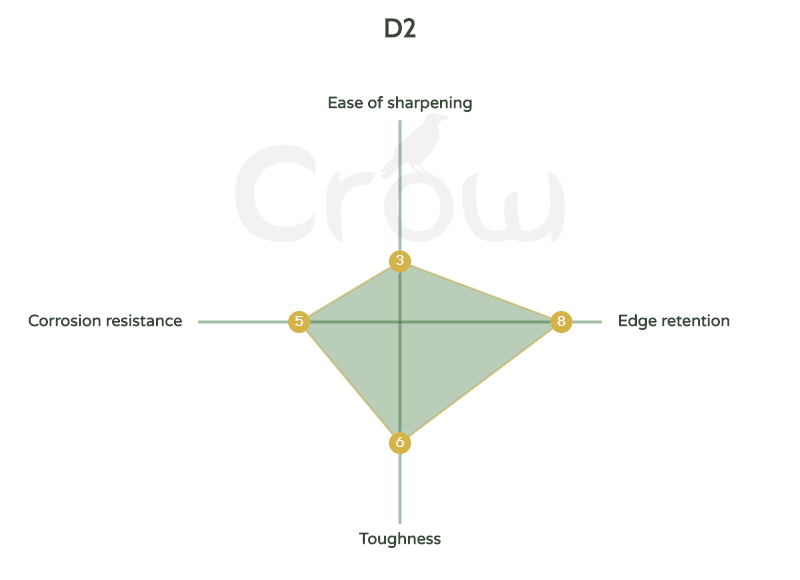

1095 vs D2 D2 has more carbon than 1095 and has high chromium content The added elements make D2 have better hardness, corrosion resistance, edge retention, and wear resistance compared to 1095 D2 is better for durability though more expensive D2 Steel Properties D2 steel is an air hardening, highcarbon, highchromium tool steel It has high wear and abrasion resistant properties It is heat treatable and will offer a hardness in the range 5562 HRC, and is machinable in the annealed condition Click to see full answerFor each property being compared, the top bar is SAEAISI 1095 steel and the bottom bar is SAEAISI D2 steel SAEAISI 1095 (SUP4, , C100S, G) Carbon Steel SAEAISI D2 (T) Chromium ColdWork Steel

1

1

Some of the most commonly used high carbon steels are 1050, 1060 and 1095 As suggested by the number, a 1050 carbon steel has 050% of carbon content, a 1060 carbon steel has 060% carbon content, and a 1095 carbon steel has 095% carbon content As carbon content rises the metal becomes harder and stronger but less ductile and more difficult to weld1095, a popular highcarbon steel for knives;It is harder but more brittle than lower carbon steels such as 1055, 1060, 1070, and 1080 It has a carbon content of % 11 Many older pocket knives and kitchen knives were made of 1095

Knife Steel Rust Testing 1095 8cr13mov D2 4hc Walmart And Y Start Youtube

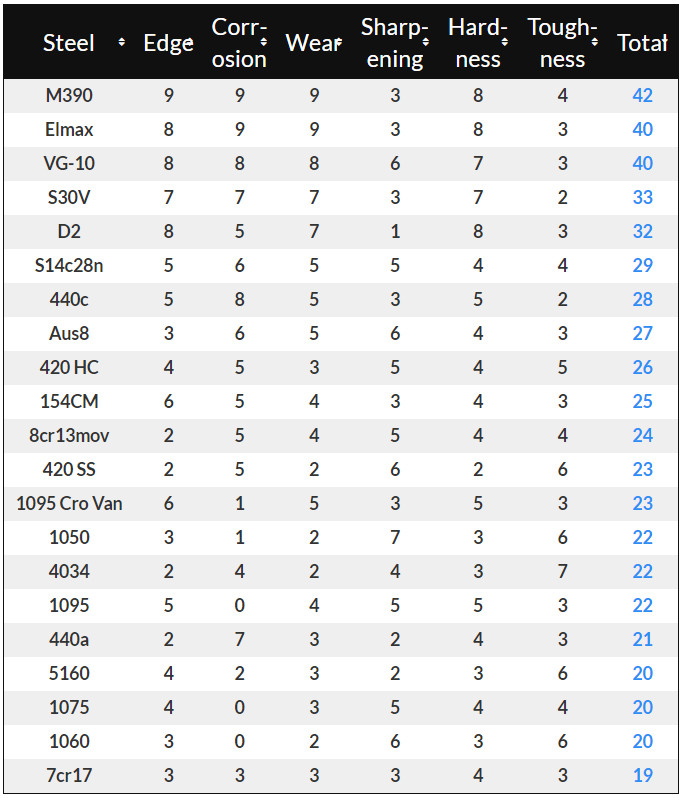

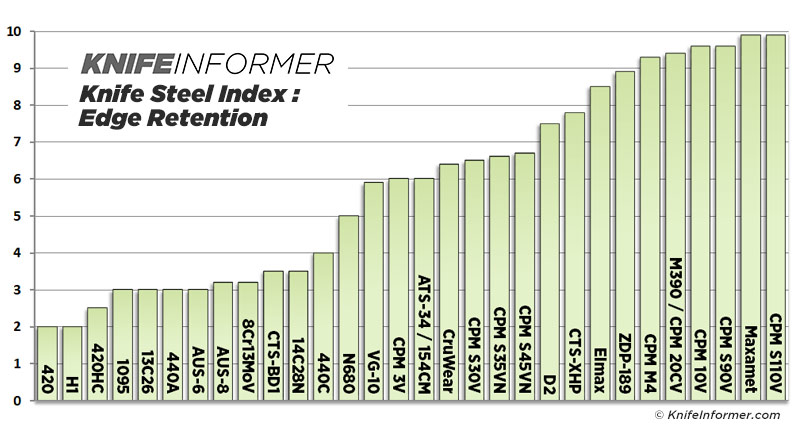

Guide To The Best Knife Steel Knife Informer

D2 is an extremely high alloy steel with a huge wear resistance and low toughness, while 1095 is a plain carbon steel with a very high toughness and low wear resistance I tend to dislike stainless steels and prefer 1095 or other high carbon types I do like D2 steel however, although to me, it seems to be a bit tougher to get an edge on it not sure why Posted PM EDT Damascus is difficult and expensive to make so if the knife is < $100 it is probably crap1095 Cro Van steel is lowend steel It's very great for knives It offers great edge retention, hardness, toughness, wear resistance, and very affordable, therefore if you intend to use it in a wet condition I wouldn't recommend it, it's carbon steel with low chromium AKA low corrosion resistance, so you' ill need to oil it and sharpen it, to keep it in shape and avoid rust

How Good Is D2 Steel Knife Blades Budgetlightforum Com

Guide To The Most Commonly Used Axe Steels Axeing

1095 carbon steel 1095 is sort of the "standard" carbon steel, it is categorized on the basis of 095% carbon 1095 qualifies as a highcarbon hardened steelAll About D2 Steel Development, Use in Knives, and D2 vs 1095 SteelWhich One Is the Better Blade Material From that point D2 became one of the most popular tool steelsD2 in Knives It took some time before D2 was used in knives The first recorded use I D2 vs 1095 Steel Which One Is the Better Blade Material?Both the D2 and 1095 are products of AISI or American Iron and Steel Institute In their composition, D2 is a high Chromium steel while Carbon level in 1095 is substantialD2, being tool steel, is harder and more wearresistant than 1095 It's also challenging to sharpen and takes longer to get a sharp edge than 1095 but will hold the edge for way longer than 1095 Because of its high chromium content, D2 will also high corrosion resistance of these two steels

1095 Steel Is It A Good Knife Steel

Ranking The Steel Ranking Articles Knife Steel Nerds

However, 430 stainless with low carbon and 16% Cr only required 3 inlbs Both sources do agree, however, that austenitic stainless steels like 304 with 18% Cr and 9% Ni require significantly higher stress to forge Steel 1095 CRO van steel is not an acronym for 1095 carbon steel Even though both 1095 & 1095 CV has similarity in carbon base and other materials, still 1095 is 1095 CRO VAN steel's dad!Typical hardnesses of 1095 carbon steel after tempering for 2 hours at different temperatures Grade Temperature, °C (°F) Rockwell hardness, HRC Heat treatment 1095 high carbon steel, carbon content 095% 5 (400) 58 HRC Normalized at 5 °C (1625 °F), water quenched from °C ( °F);

Is 1095 Steel Good For Knife Making

Is D2 Steel Good For Knives Complete Steel Guide Knife User

Alongside edge geometry and design, blade steel is a critical element that determines how a knife performs BladeForums has ZERO TOLERANCE for extremism or calls of violence #2 The steel that our fellow forum user The problem with the W series is that the carbon content varies so much However, if you have W2 like The New Jersey Steel Baron carries it will be a whole lot like 1095 because the only difference will be a little vanadium Just enough to form some vanadium carbides but not enough to effect the depth of hardening What is Carbon Steel?

38 Sword Of Auron In Just Spring Steel D2 Steel Battle Ready V Hs Blades Enterprise

Caring For Carbon Steel Knives

In choosing the best pocket knife you should pay particular attention to the type of steel used in the blade For their composition, D2 is high on chromium steel, while 1095 has substantial levels of carbonAs a result, D2 can be called more or less a semistainless material, and 1095 is a classic high carbon steel material D2 steel is an airhardened tool steel that is considered "semistainless" because of its high chromium content (about 12%) This means D2 is more corrosion resistant that other High Carbon Steel but still has great wear resistance and toughness D2 is a happy medium between stainless and high carbon steels D2 steel is an alloy of high carbon and chromium giving it very superior hardness, wear, and corrosion resistance as compared to 1095 steel In terms of cost, Carbon steels are always cheaper than alloy steel but for long and sturdy use, D2 steel is preferable 1075 VS 1095 steel

Is D2 Steel Good For Knives Complete Steel Guide Knife User

Is D2 Tool Steel A Carbon Steel Or A Stainless Steel Youtube

High Carbon D2 Steel 1095 15n Hand Made Custom Bowie Red Knives

Carbon Myth

D2 Vs Cpm S30v Steel Which Is Better For Knives Knifeup

38 Sword Of Auron In Just Spring Steel D2 Steel Battle Ready V Hs Blades Enterprise

The Ultimate Guide To Choosing The Best Knife Steel

Steel And Knives A Comparison And Explanation Survival Monkey Forums

Does D2 Tool Steel Make A Good Knife Knives Illustrated

The Difference Between 440c Steel Vs D2 Compared Guide Knifeyellowpages

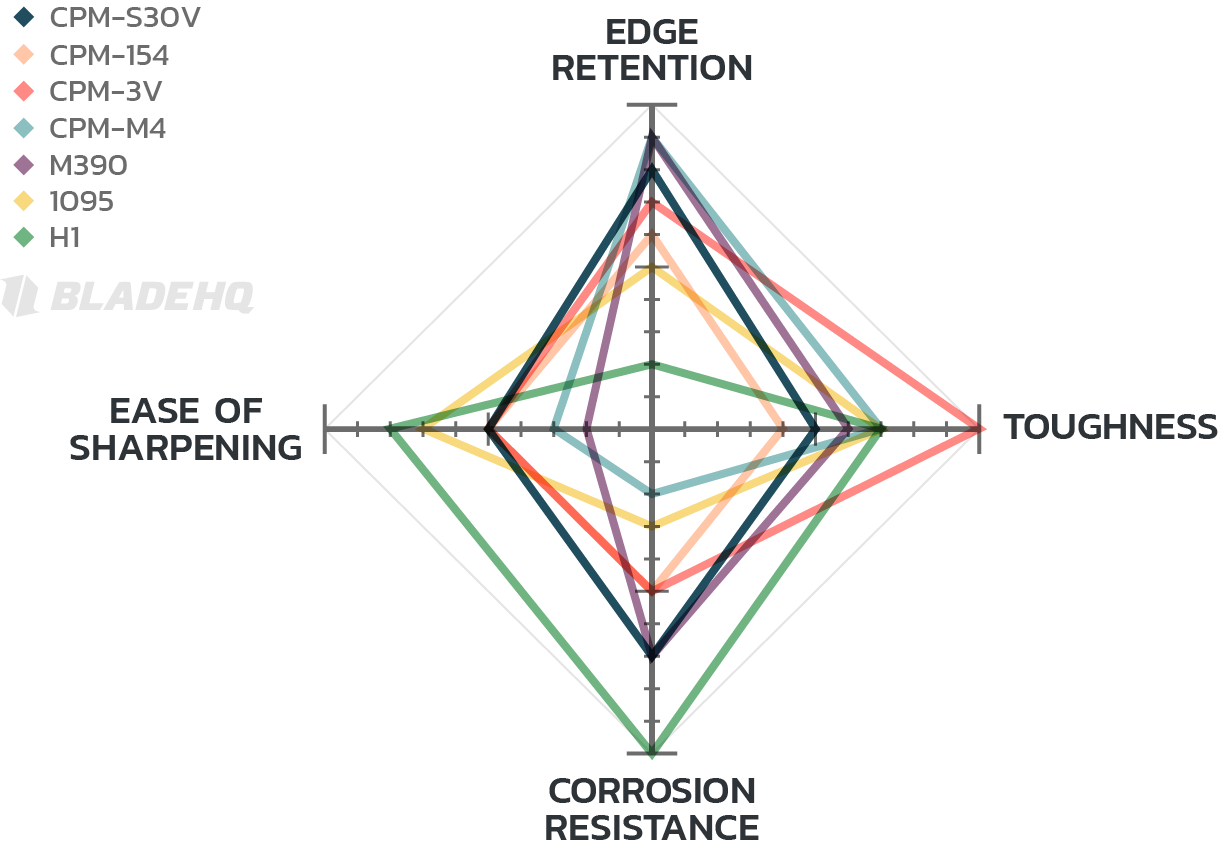

Best Knife Steel Comparison Steel Charts Guide Blade Hq

1

Carbon Vs Stainless Steel In Knives Knife Steel Nerds

1095 Carbon Steel Alpha Knife Supply Aks

Guide To The Best Knife Steel Knife Informer

Knife Blade Materials

How Good Is 1095 Carbon Steel The Complete Guide

Ranking The Steel Ranking Articles Knife Steel Nerds

Is D2 Steel Good For Knives

Which Steels Are Easiest And Most Difficult To Forge Knife Steel Nerds

1095 Steel Unleashed Pushing Its Edge Retention To The Max Youtube

All About D2 Steel Development Use In Knives And Properties Knife Steel Nerds

1095 Steel Review Composition Properties Applications

15n Steel Damascus Steel L6 Nickel Steel

8 50 Damascus Steel Blank Bladed For Knife Making Sh Etsy Knife Knife Making Damascus Steel Blanks

D2 Steel Is It A Good Knife Steel

Knifeindustry Instagram Posts Gramho Com

How To Pick The Best Steel For Every Knife Knife Steel Nerds

Lansky Sharpeners The Secrets Of Steel Part 2 High Carbon Steel

Guide To The Best Knife Steel Knife Informer

D2 Steel Is It A Good Knife Steel

Best Knife Steel Comparison Steel Charts Guide Blade Hq

1095 Steel Review Composition Properties Applications

S30v Vs D2

1095 Steel Review What Is It And Is It Good

Top Grade Latest D2 Metal Shear Bar Blades 1095 Carbon Steel Blade Buy Top Grade Shear Bar Blades Latest D2 Metal Shear Blade 1095 Carbon Steel Blade Product On Alibaba Com

Steel Choice And You Chefknives

All About D2 Steel Development Use In Knives And Properties Knife Steel Nerds

Lansky Sharpeners The Secrets Of Steel Part 2 High Carbon Steel

38 Sword Of Auron In Just Spring Steel D2 Steel Battle Ready V Hs Blades Enterprise

D2 Vs 1095 Steel Which One Is The Better Blade Material

Cruwear Vs D2 Spyderco Forums

What Is The Difference Between W2 Steel Vs 1095 Knifeyellowpages

Why Reiff Knives

Edge Retention Test Aus8 Vs D2 Ontario Rat 1 Steel Options Compared Youtube

1095 Steel Is It A Good Knife Steel

440c D2 12crcustom Handmade Hi Carbon Steel 1095 Full Tang 13 3 Inches Nakiri Knife With Leather Sheaths Buy 440c D2 12crcustom Handmade Hi Carbon Steel 1095 Full Tang 13 3 Inches Nakiri Knife Fixed Blade Knife With Leather Sheaths Stainless

What Is The Difference Between W2 Steel Vs 1095 Knifeyellowpages

Knifeindustry Instagram Posts Gramho Com

38 Sword Of Auron In Just Spring Steel D2 Steel Battle Ready V Hs Blades Enterprise

Amazon Com Gcs Handmade Hunting Knife Micarta Handle D2 Tool Steel Tactical Knife Skinning Knife Survival Knife With Buffalo Hide Leather Sheath Full Tang Blade Designed For Hunting Skinning Edc Gcs

Custom Hand Made 1095 Carbon Steel Hunting Knife With Leather Strap Handle High Carbon Steel Carbon Steel Leather Straps

D2 Steel Is It A Good Knife Steel

Knife Blade Materials

W2 Tool Steel Common Blade Steel For Knives Complete Info

Amazon Com D2 Steel Knife Full Tang Bushcraft Knife Hunting Knife Handmade Tracker Knife Hand Forged Fixed Blade Knives Camping Knife Edc Knife Hunting Knives With Micarta Handle Leather

What Is 1095 Cro Van Steel Top 3 1095 Cro Van Knives Review Howtotactical

Sword Steels 101

Knife Blade Steels And Facts Woodworld Of Texas

D2 Vs 1095 Steel Which One Is The Better Blade Material

Amazon Com Sk Damascus Knives D2 Steel Knife Custom Handmade 12 Beautiful D2 Steel Hunting Bowie Knife Camel Bone Hard Wood Handle With Leather Sheath Tools Home Improvement

D2 Steel Complete Information Best Blade Steel For Hunting

What Is The Difference Between W2 Steel Vs 1095 Knifeyellowpages

Sword Steels 101

Katana Sword S Blades 1045 Carbon Steel 1060 Carbon Steel Folded Steel 1095 Carbon Steel Full Tang Sharpness Swords Aliexpress

Guide To The Best Knife Steel Knife Informer

Handmade D2 Steel Karambit Knife Vk5003 Vk Damascus Knife

Custom Handmade Damascus Hunting Knife Handle Patina Finish Etsy In 21 Damascus Steel Leather Sheath Damascus Hunting Knife

Is 1095 Steel Good For Knife Making

Is 1095 Cro Van Steel Good For Knives

Is 1095 Steel Good For Knife Making

Knife Steel Information Crow

Not Found Ontario Knife Knife Tool Steel

Tracker Knife Damascus Hunting Knives Brown Black Micarta Etsy Leather Sheath Damascus Steel 1095 Steel

Why Reiff Knives

Top Grade Latest D2 Metal Shear Bar Blades 1095 Carbon Steel Blade Buy Top Grade Shear Bar Blades Latest D2 Metal Shear Blade 1095 Carbon Steel Blade Product On Alibaba Com

D2 Vs 1095 Steel Which One Is The Better Blade Material

Best Knife Steels In 21 Steel Charts Guide By A Marine

Is D2 Steel Good For Knives Complete Steel Guide Knife User

How To Heat Treat D2 Psf27 And Cpm D2 Laptrinhx News

0 件のコメント:

コメントを投稿